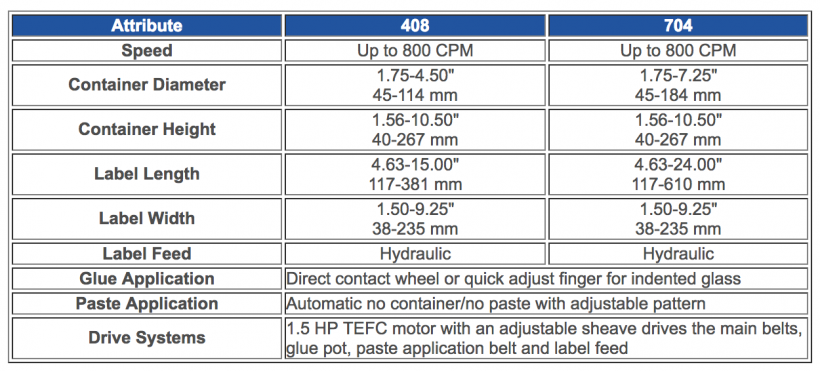

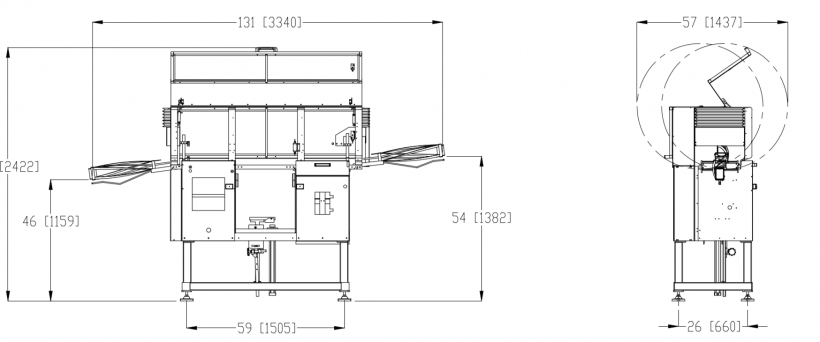

Pneumatic Scale Angelus Burt 408 Labeler Machine

The Burt 408 can apply full-wrap labels to cylindrical containers of virtually any material at speeds up to 800 CPM. A variety of conveying mechanisms and adjustable belt tighteners ensure positive container control. Additionally, the machine can utilize a broad range of labeling materials including papers, foils, plastics and laminates for maximum flexibility. The Burt promotes excellent label control by employing a unique hydraulic feed system, which smoothly and accurately positions labels. An optional second feed allows label loading while running. Also, the Burt offers positive label pickup without glue slinging for a neat appearance.

Label Specifications

• Paper weight 52 to 55 lbs. Means 500 sheets 24” x 36” paper will weigh 52-55 lbs. 55 lbs. = 89.5G/M2.

• Length and width of paper label +/- 1/64”.

• Normal labels .0045’ thick and 1000/stack = 4 1⁄2”.

• Grain of paper should run the length of the paper.

• Allow for an overlap of 1/2″ to 5/8″.

• The pick-up end of the label (under-lap) should not be varnished for approximately 3⁄4 inch for best adhesion.

• Single feed capacity is about 12”, slightly less with secondary feed.

Glue Specifications

• The hot melt pick-up glue selected depends on many variables. These can include: can temperature, moisture, and production speed. Contact glue supplier for final recommendations.

Paste Specifications

• The cold lap paste selected is normally a potato-dextrin base or starch paste. For pressurized applicators require approximately 1,500 CPS paste.