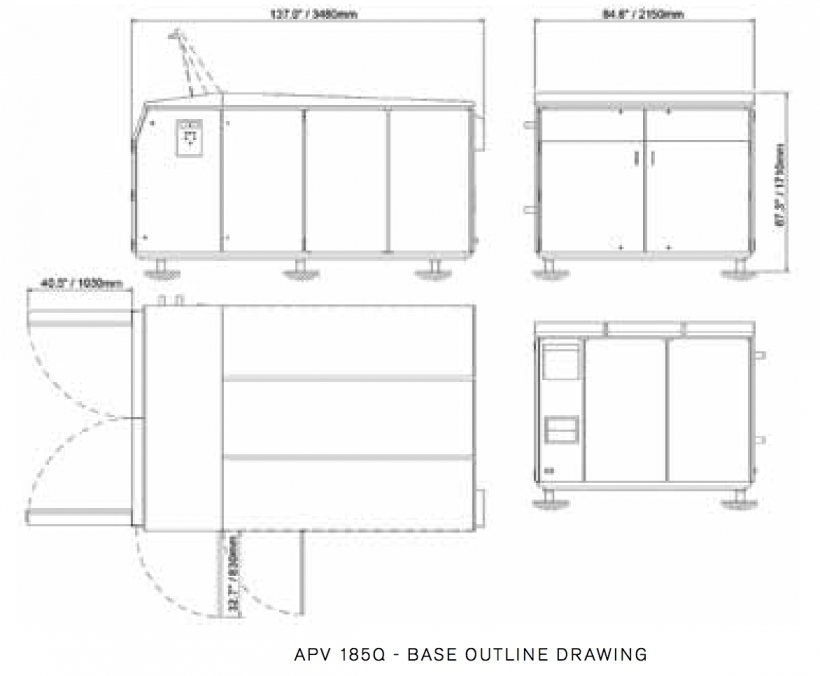

APV High-pressure Homogenizer Rannie 185Q / Gaulin 185Q and Rannie 275Q

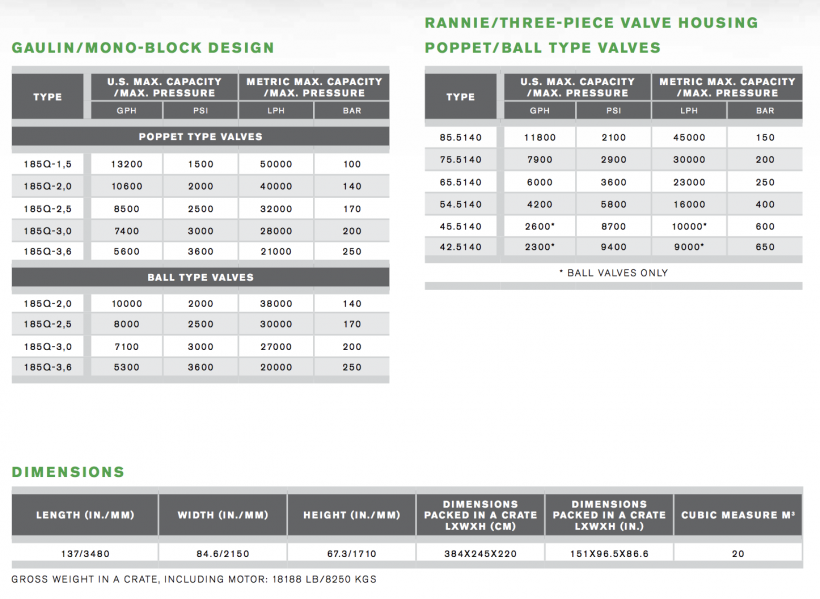

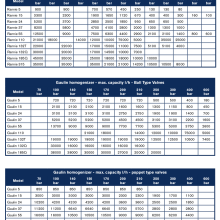

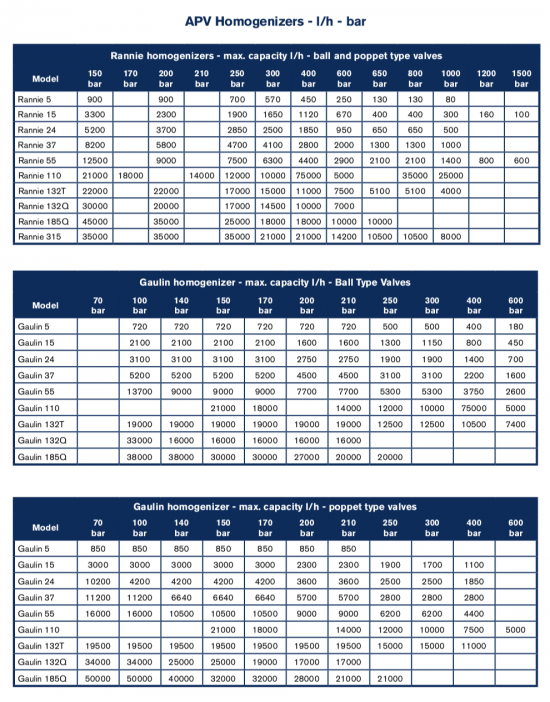

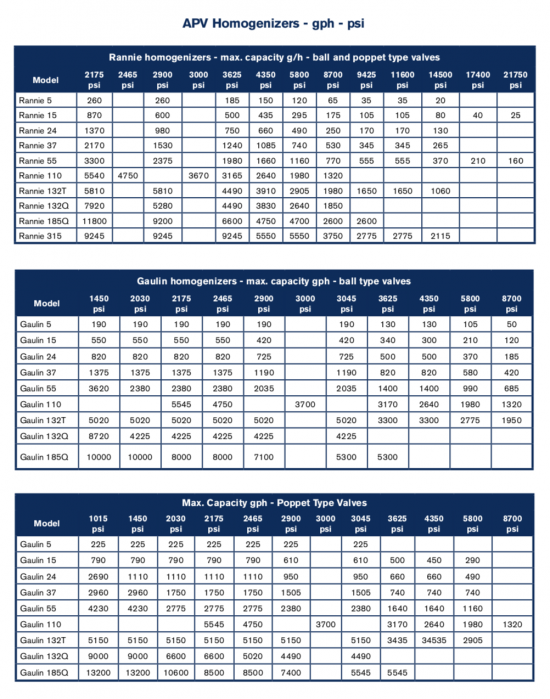

The APV 185Q is a high performance homogeniser, capable of functioning at flow rates up to 50,000 litres per hour (13,209 gallons per hour) and pressures of 650 bar (9427.4 PSI). It provides the ideal solution for your homogenisation applications.

Cost Efficient and Reliable

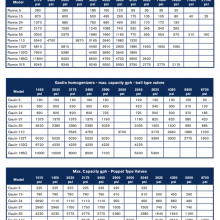

The new homogeniser demonstrates exceptional operational efficiency. Its latest technology design combines low energy and water consumption with reliable operation. With flow rates ranging from 10,000 – 50,000 litres per hour (2,642-13,209 gallons per hour), customers can select exactly the right version for their needs.

Environmentally Friendly

The APV 185Q is equipped with a low noise cabinet as standard. Other environmentally friendly features include a cooling system, which minimises the use of water by engaging automatically only when the oil temperature moves outside the critical range of 40-50°C (104-122°F). The APV 185Q is also designed to eliminate the risk of water contamination in the oil.

Ease of Inspection

The low noise cabinet has panels and doors for inspection and maintenance. The interior of the APV 185Q is conveniently lit for ease of inspection.

Basic Machine

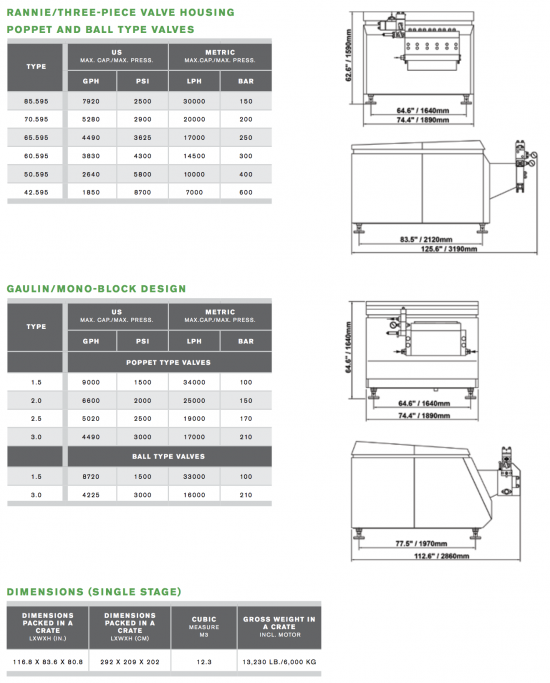

The APV 185Q homogeniser, a five-plunger, reciprocating pump, is fitted with a single-stage homogenising valve (optional two-stage) with hydraulic actuation. The APV 185Q incorporates a durable slow-speed Power End that reduces vibration and noise. Easy access to the hydraulic actuation system, oil treatment unit and other auxiliary systems simplifies maintenance saving time and money. Liquid End options include a three-piece valve housing (Rannie) and a monoblock design (Gaulin). Design features of both Rannie and Gaulin simplify routine maintenance.

Standard Options for APV 185Q :

• Two-stage hydraulic valve actuation (HVA)

• Aseptic cylinder design

• High-pressure outlet connections

• Micro-Gap® homogenising valve

• Motor starter

• Controllers for automatic pressure control

• Control cabinet, stainless steel

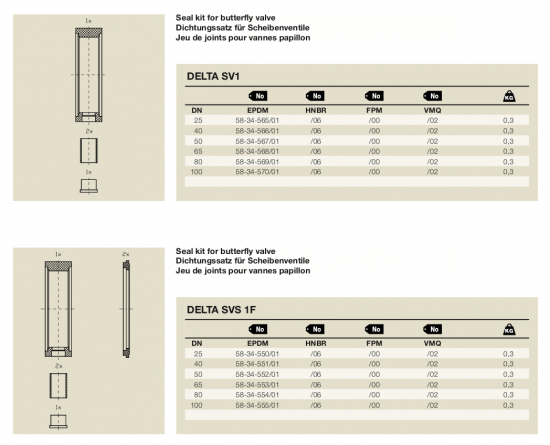

• Choice of materials for cylinder block, plungers, homogenising valves, packings, pump valves, valve seats, and seals.

• Pulsation dampener(s): inlet and outlet

• Flow meter for lubrication oil, monitoring slide bearings condition

• Pressure transducer for lubrication oil pressure (4-20 mA output)

• External cooling fan/main motor