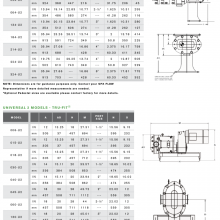

Waukesha Rotary Positive Displacement Pump Universal II

The Universal 2 Series Pumps is the latest expression of this tradition. They combine 3-way mounting versatility introduced by the Universal 1 with new features that extend pump life and improve sanitary performance. Pump is available in CIP-able configurations.

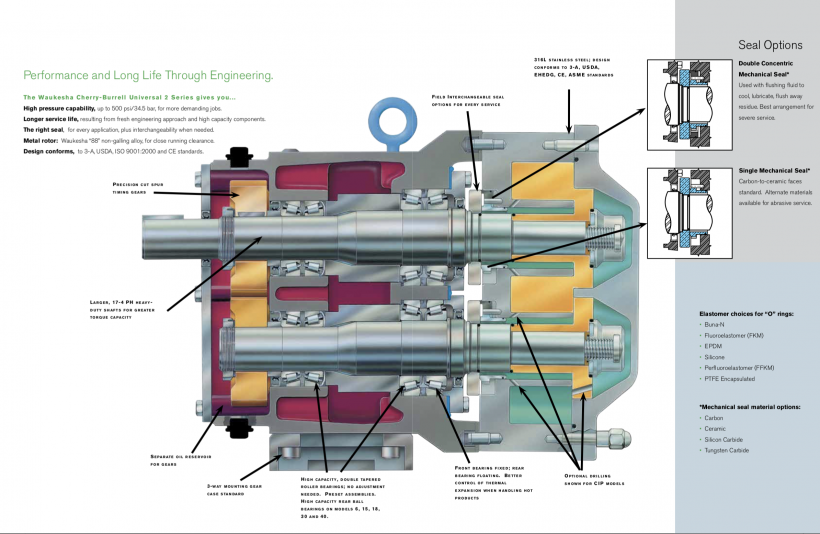

PRODUCT FEATURES AND BENEFITS

Sanitary Features :

• CIP capability available. Pump body has optional internal flat body profile and will free drain with vertical ports. Optional rotor and body hub drilling provided for difficult CIP cleaning applications.

• Cover is free draining in horizontal or vertical port positions.

• Rotor/shaft connection sealed from product zone.

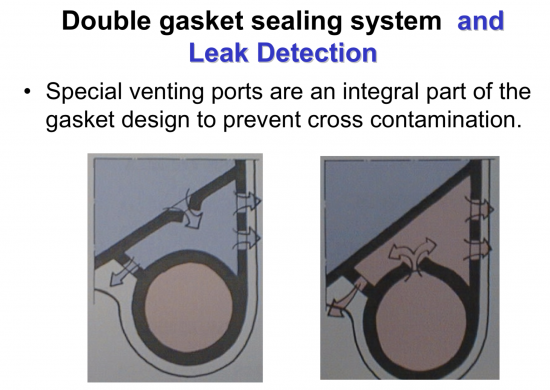

• Single mechanical seals standard. Optional double mechanical seals also available.

• Seal flush optional: seal areas interconnected to improve circulation and draining of seal flush fluid. Steam-In-Place also is optional.

• Stainless steel bearing frame optional on models 006 to 220.

• Aseptic design (Option)

Long-life Features :

• Up to 500 psi (34.5 bar) pressure capability.

• Special rotor nut designed for extended service without loosening.

• No bearings in the product zone.

• Larger diameter 17-4 PH shafts for greater strength and stiffness. Helps eliminate vibration; extends seal life.

• Heavy duty bearing frame (stainless steel available as an option).

• Double tapered roller bearings.

• Greased lubed bearings for positive lubrication to all bearings over entire speed, temperature and pressure range.

• Body retaining screws for maintaining mechanical seal contact during inspection.

• Extended outer seal life. A wave spring, instead of an O-ring, mechanically loads the seal.

• O-Ring on inner seal, seals on clean surface as seal moves due to wear.

• Unique mechanical seal design utilizes 3 pin stationary seal and special design shaft for rotary seal.

Installation Features :

• Bidirectional flow. Rotors, locked with belleville washers and torqued nuts, rotate securely in either direction. No more flow direction/shaft position specifications.

• Interchangeable installation dimensions with Universal 1 and Universal Lobe PD pumps. (Except for 320 and 324 sizes)

• Versatile 3-Way mounting of gear case, including vertical alignment of ports.

• Upper or lower shaft position.

• Jacketed or vented cover optional.

• Non-galling Waukesha “88” alloy rotors standard; permits running at tighter clearances and pumping a wide range of viscosities. 316L stainless steel lobe rotors also available.

• 316L stainless steel pump body and cover.

• Electro-polish of product contact surfaces, optional.

Typical product applications :

• Food and Beverage : Soups, Stews, Tomato Paste Vegetables, Dressings, Chocolate, Fats & Oils Batters, Cream Fillings, Brewery, Wort, Soft/Fruit Drinks.

• Dairy : Cream, Milk, Cheese Curd & Whey, Cottage Cheese, Yogurt.

• Pharmaceutical/Cosmetics : Pill Pastes, Syrups, Extracts, Slurries Face Creams & Lotions, Hair Styling Gels & Liquids, Dyes & Alcohols.

• Chemical/Industrial : Solvents, Paints, Fuels, Resins, Polymers & Sludges, Oil & Lubricants, Soaps.