Waukesha Universal Twin Screw (TS) Series Pump

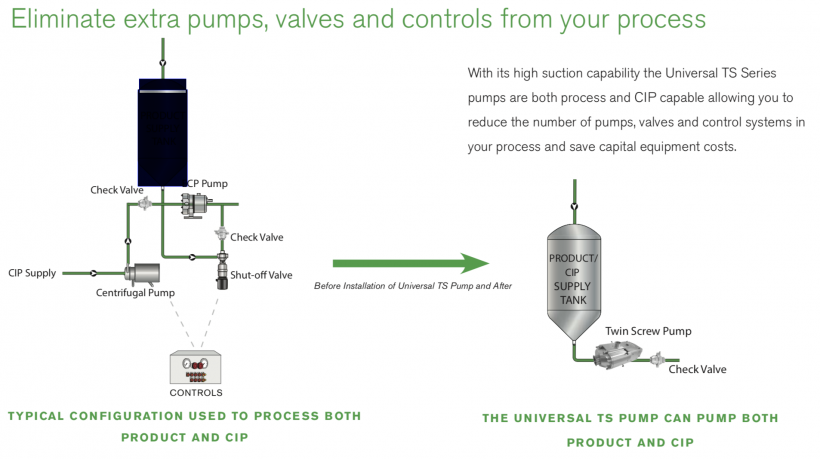

Universal Twin Screw (TS) Series Pump eliminates extra pumps, valves and controls from your process. With its high suction capability the Universal TS Series pumps are both process and CIP capable allowing you to reduce the number of pumps, valves and control systems in your process and save capital equipment costs.

Features and Benefits :

• Reliable performance – Screws made from Waukesha Alloy 88 non-galling material allow the pump to run through incidental contact and reduce risk of pump damage if screws make contact

• Gentle product handling – Pumps large particulates without degradation

• Responsive service – Extensive global distribution network with certified repair centers provide quick response times for parts and service

• Easy maintenance – Front loaded access to product side seals

• Process flexibility – Low inlet pressure requirement and a wide range of operating speeds allow for multiple duties including process and CIP supply. Bi-directional flow capability without making modifications to the pump.

• Smooth operation – Reduces slip pulse in low inlet pressure, low viscosity, and high pressure conditions

• Reduced noise levels – Operating principle virtually eliminates pressure fluctuations

Sanitary Features

• CIP capability standard. Pump body and cover are free draining.

• Screw/shaft connection sealed from product zone.

• Single and Double mechanical seal options

• Seal flush ports for optional double seal is included on all models

• Steam-In-Place capable;

• Standard Stainless steel gear case

Installation Features

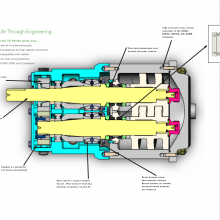

• Splined shafts and screws provide positive engagement and ease installation of the screws.

• Bidirectional flow. Screws, locked with Belleville washers and torque nuts, rotate securely in either direction. No more flow direction/shaft position specifications.

• Non-galling Waukesha “88” alloy screws standard; permits running at tighter clearances and pumping a wide range of viscosities.

• 316L stainless steel pump body and cover

• The product seal and barrier seal parts are identical to simplify assembly and reduce the number of different components.

• All pumps are performance tested prior to shipment.

Long-life Features

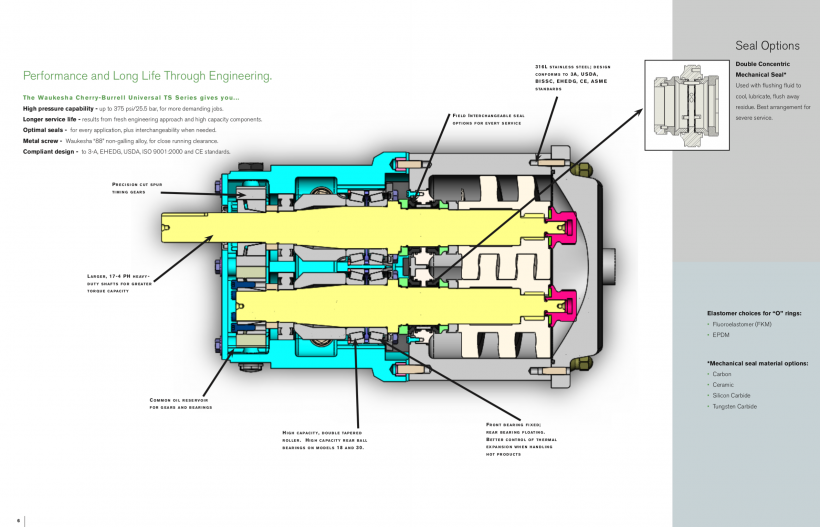

• Up to 375 psi (25.5 bar) pressure capability.

• Special rotor nut designed for extended service without loosening.

• No bearings in the product zone.

• Larger diameter 17-4 PH shafts for greater strength and stiffness. Helps eliminate vibration; extends seal life.

• Heavy duty bearing frame stainless steel standard

• High Precision Needle Roller bearings, 4-point angular contract bearings and cylindrical roller bearings ensure screw timing is maintained throughout the life of the pump

• Oil-lubricated bearings for positive lubrication to all bearings over entire speed, temperature and pressure range.

• Body retaining screws for maintaining mechanical seal contact during inspection.

• Unique mechanical seal design utilizes common parts for inner and outer seal seats and rotary seals in a compact design.

Universal Twin Screw (TS) Series Pump Typical product applications :

• Food and Beverages : Soups, Stews, Tomato Paste Vegetables, Dressings Chocolate, Fats & Oils Batters, Cream Fillings Brewery, Wort, Soft/Fruit Drinks, Meat Processing.

• Dairy : Cream, Milk, Cheese Curd & Whey Cottage Cheese Yogurt.

• Pharmaceutical/Cosmetics : Pill Pastes, Syrups, Extracts, Slurries Face Creams & Lotions Hair Styling Gels & Liquids Dyes & Alcohols, Soaps, Cosmetics.

• Chemical/Industrial : Solvents, Paints, Fuels, Resins, Polymers & Sludges, Oil & Lubricants.