Waukesha Ball Valves

PRODUCT FEATURES AND BENEFITS

• All stainless steel construction; forged bodies

Only forged housings from certified 316L or 304 stainless steels; non- porous, smooth surfaces for easy maintenance, secure assembly and corrosion resistance.

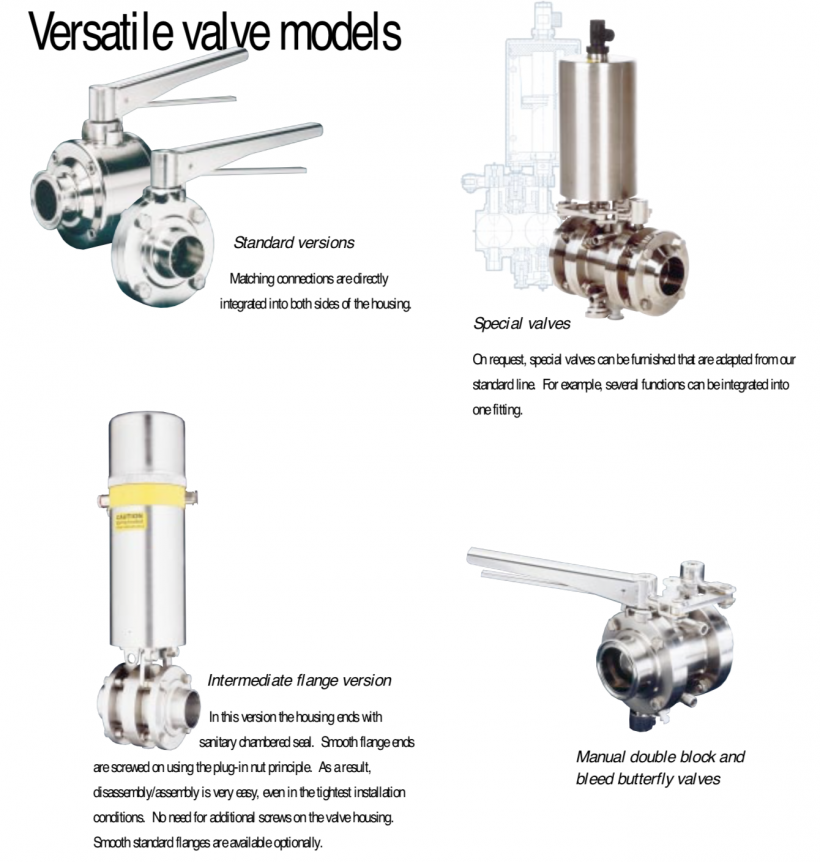

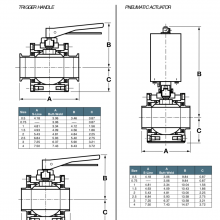

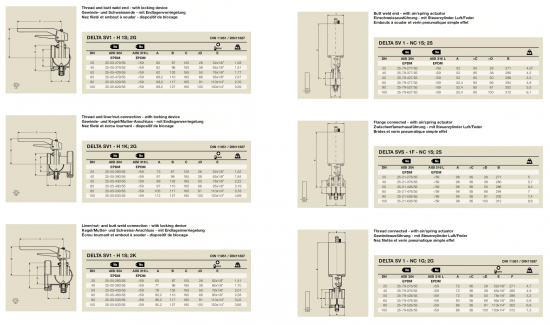

• Versatile in sizes and connection standards 1/2-inch to 4-inches (12mm to 102mm) S-Line clamp or Butt-Weld; intermediate flange ends.

• Rugged, FDA-approved seal materials

Meet wide-ranging product and process requirements with FDA-approved seal materials that offer reliable, long-life service. Reinforced PTFE seats for ball valves. Ball valve features 3-piece design with floating seals.

• Cavity flush feature on ball valve

The unique design of the ball valve results in a natural flushing action within the valve cavity.

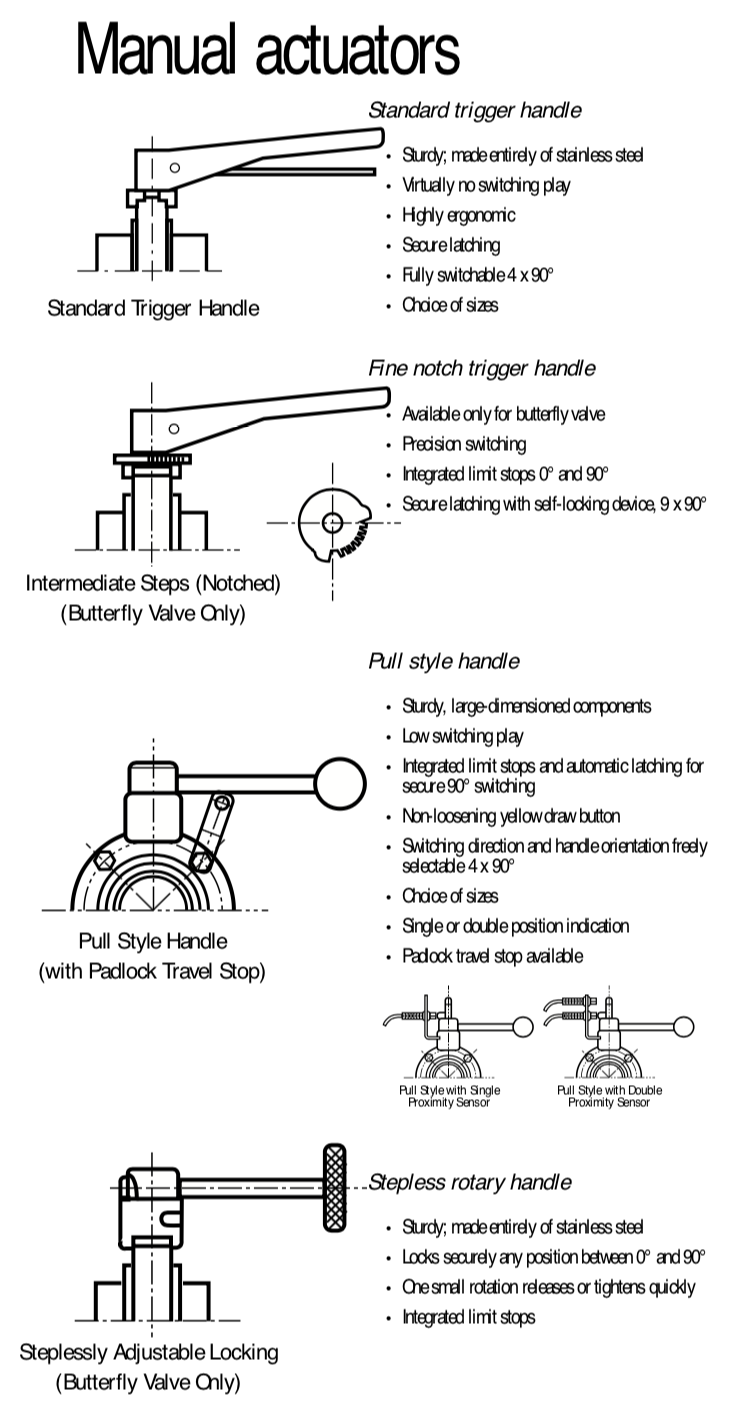

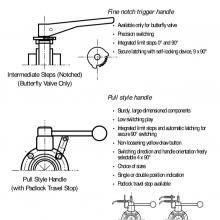

• Sturdy, ergonomic operating handles to answer any preference

Two basic operating handles, trigger and pull style, are available in fine- notch, stepless and lockable versions with single or double proximity sensors that accommodate specific control circumstances. Each is made of stainless steel.

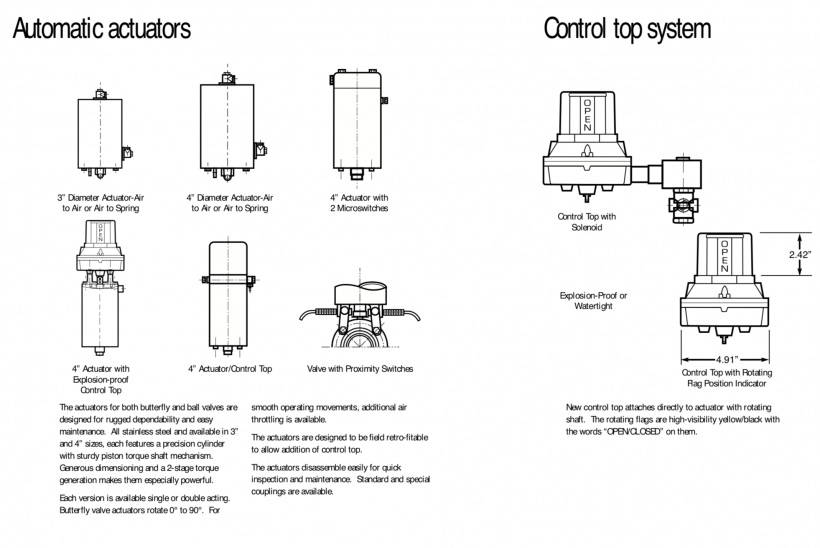

• Precision stainless steel actuators

Generously dimensioned and available in several sizes, either single or double acting, this complete line of actuators offer extremely long service life.

• Ball valves (1/2-inch through 4-inch) are full port dimension There is no restriction in the product opening through the ball.

• Actuators easy to disassemble and maintain

Standard O-rings enable an economic start-up even after numerous switching cycles.

• Torsion-free mounting brackets

Mounting brackets assemble fast and stress-free. One size fits several nominal widths.

• Wide selection of control options

– Control top (NEMA 4) with proximity switches; addition of solenoid is optional

– Namur base explosion-proof top

– Namur base water-proof top

– Control top (NEMA 4) with micro-switches and/or solenoid