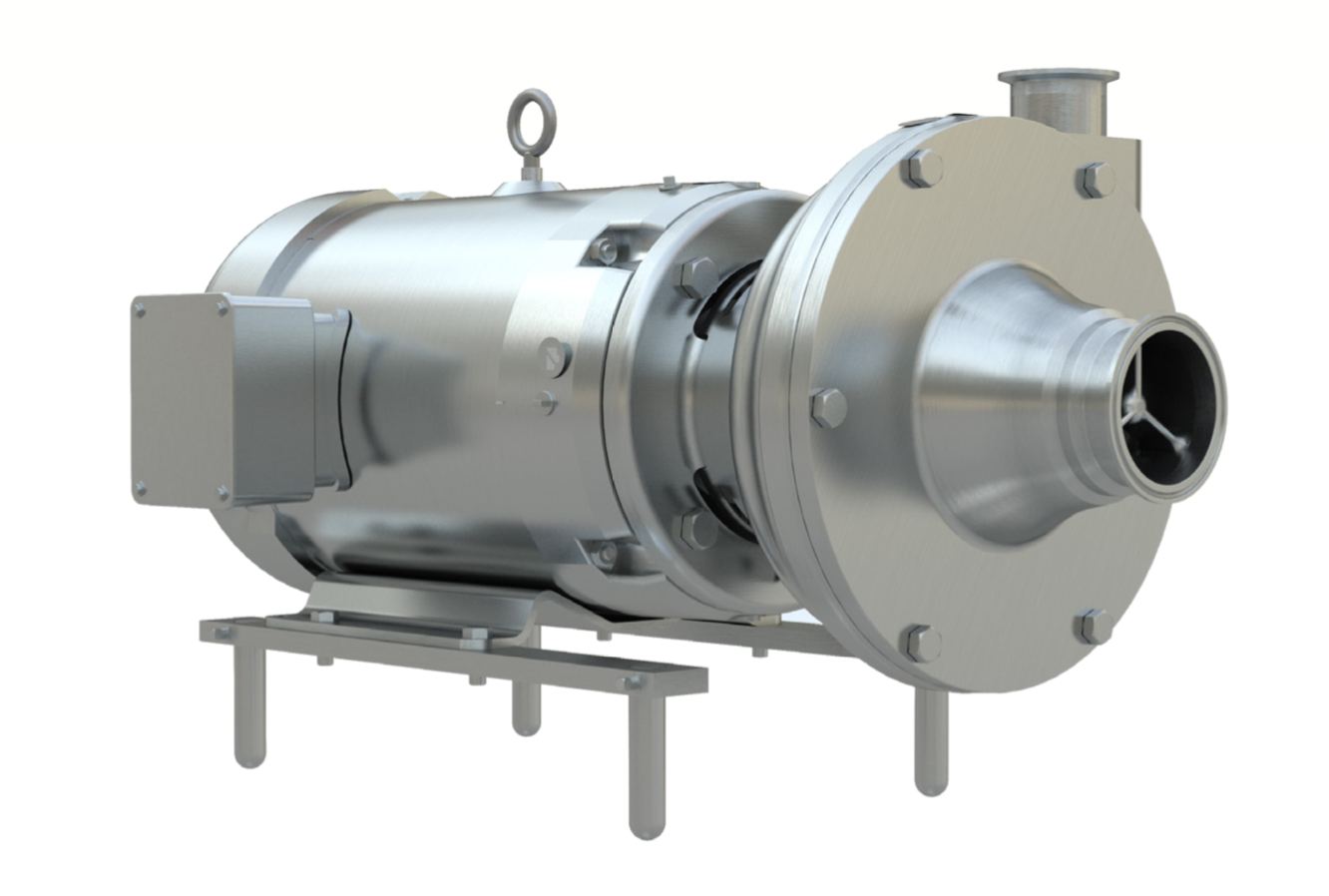

Waukesha E-Series Pump

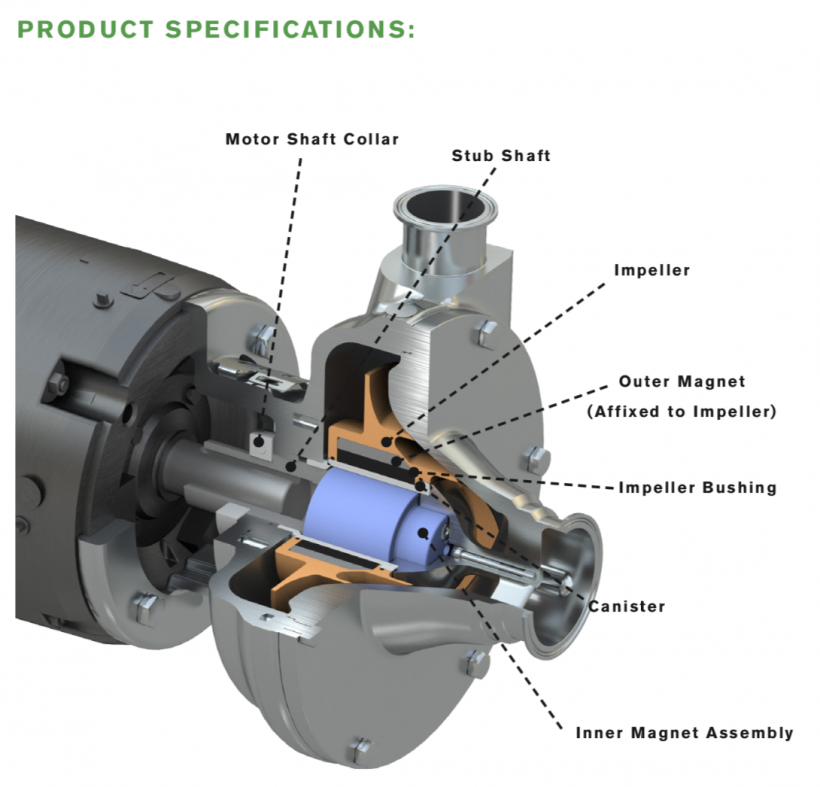

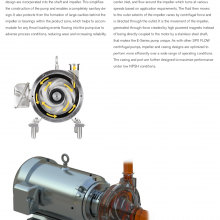

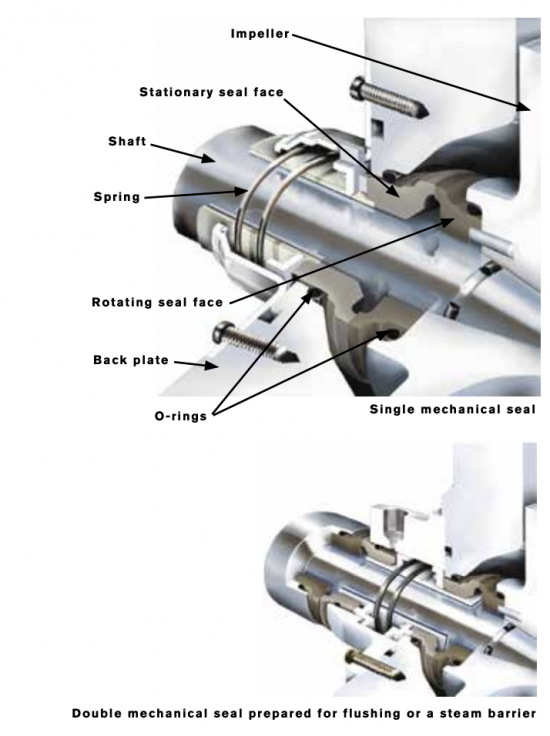

The Waukesha E-Series Pump is a leak-free (Leak-free based on the absence of a mechanical seal) design that incorporates an innovative magnetic drive system that removes the necessity of having a mechanical seal in the assembly. Removing the mechanical seal takes away the requirement for seal water in all applications as well as eliminates costs by increasing up time of the pump. No more stopping a process due to a leaking mechanical seal and no more worries of potentially contaminating the product with seal water.

Product Benefits And Features :

• No seals to replace or maintain equating to:

- – increased uptime, lower maintenance costs

- – less potential for contamination

- – less infrastructure required (no waterlines or controls for seal flushing)

• Key components manufactured from bar stock or forged for high durability, precision and efficiency

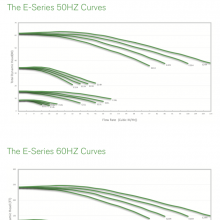

• Pump is designed to virtually eliminate issues associated with vibration, noise, short bearing life, low NPSH requirements, high seal maintenance costs and poor tolerance to adverse operating conditions

• Reliable and heavy duty design

• Energy efficient

• 3-A Certified and EHEDG (European Hygienic Engineering & Design Group) compliant

• Designed for CIP (Cleaning in Place) as well as SIP (Sterilizing in Place)

• Suitable for a wide variety of food, beverage and pharmaceutical products

• Utilize one piece flow manufacturing process for quick ship deliveries

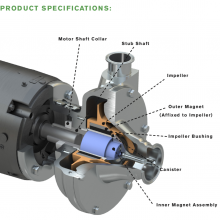

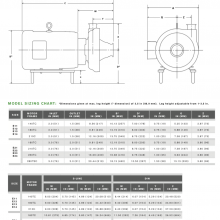

PRODUCT SPECIFICATIONS

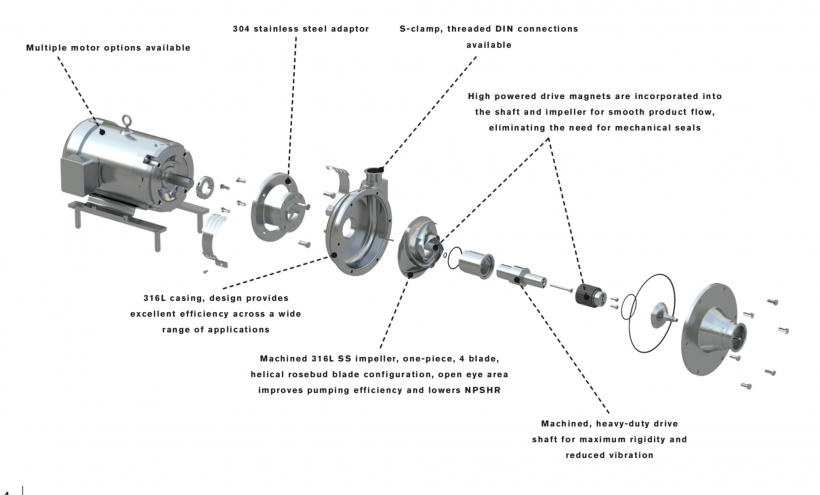

Pump Motor Bracket :

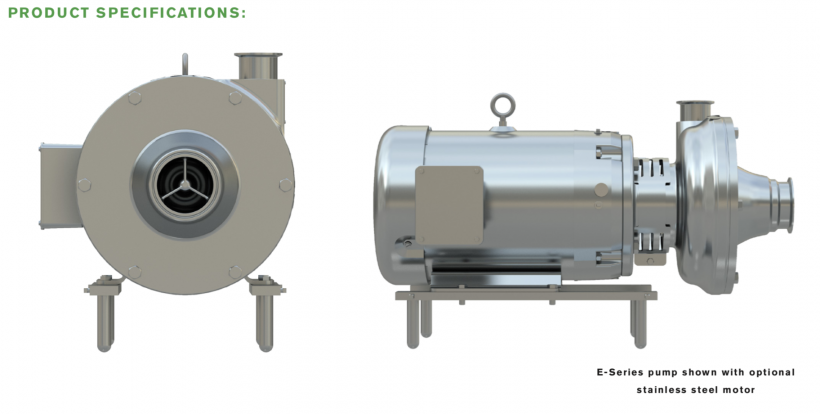

• Stainless Steel Motor Types:

• NEMA C-Face standard frame motor

• TEFC and wash down enclosures optional

• Explosion-proof and stainless steel optional

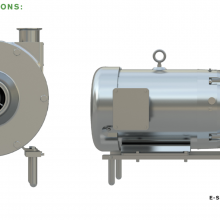

• Single phase or three phase, 60 or 50 Hertz Casing:

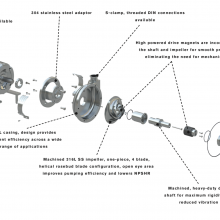

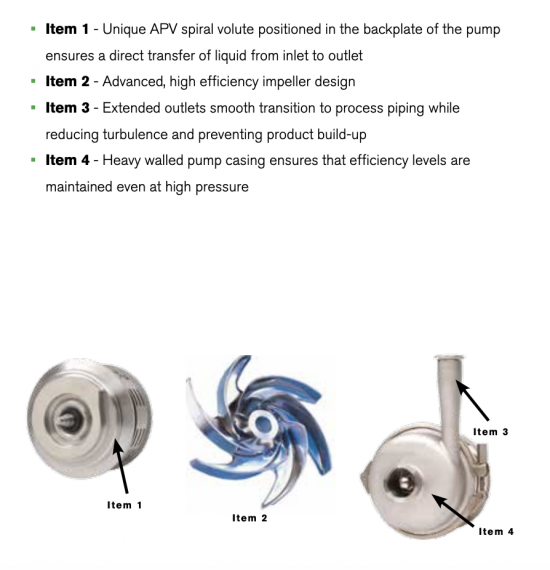

• 316L, satin exterior with sanitary finish in product zone

• Designed to provide good efficiency over a wide range of operating conditions

• Discharge can be rotated in 45 ̊ increments

• Interior of casing is free of sharp corners for easy, complete cleaning Port Connections:

• S-Clamp

• Threaded DIN

Mounting :

• Heavy duty bolts secure pump casing to adaptor frame Cover:

• 316L stainless steel

Impeller :

• Machined from solid bar 316L stainless steel

• One piece design with 4 blade, helical rosebud configuration

• Open impeller eye area and tight front clearance improves pumping efficiency and lowers NPSHR

• Cut to specifications based on application requirement

OPTIONAL EQUIPMENT

• Special stainless steel polishing including electro-polishing

• Case Drain Connections

• Stainless Steel Tubular Base Mountings

• Cart Mounting

• Various Motor Finish Options are Available

Typical Product Applications :

• Clean-In-Place (CIP) : Food, Dairy

• Dairy : Whey, Cream, Milk, Sweetened Condensed, RO/UF Systems

• Beverage : Water, Energy Drinks, Juices, Carbonated Soft Drinks, Brewery, Wine, Spirits

• Bakery and Confectionery : Glazes, Fats & Oils, Flavorings, Sweeteners, Yeast Slurry, Syrups

• Pharmaceutical/ Cosmetics : Emulsions, Extracts, Slurries, Syrups, High Purity Water, WFI, Dyes, Alcohols, Essential Oils